< Previous | Contents | Next >

Section 10-3 Offshore Chains and Chain Accessories

1021. Application

1. The requirements in this Section apply to the tests and inspection for the approval of manufacturing process of the offshore chain and chain accessories (hereinafter called chains and chain accessories) specified in Pt 4, Ch 8, 401. 2 of the Guidance.

2. Chains and chain accessories are to comply with the additional requirements, which are 1001 for offshore chains and 1011 for offshore chain accessories, other than the above 1.

1022. Materials

1. Kind of materials, mechanical properties used in chains and chain accessories are to comply with

Pt 2, Annex 2-9 of the Guidance.

2. Manufacturers propriety specifications for R4S and R5 may vary subject to design conditions and the acceptance of the Society.

3. Each Grade is to be individually approved. Approval for a higher grade does not constitute appro- val of a lower grade.

1023. Chain Approval of manufacturing process

1. Chains are to be manufactured only by works approved by the Society.

2. Data to be submitted

(1) Kind of chains

(2) Manufacturing process

(3) Materials

(4) Heat treating method (including furnace types, controlling and recording of temperature and chain speed and allowable limits, quenching bath and agitation, cooling method after exit)

(5) Diameter of test chain, maximum chain diameter

(6) In addition to the above, the following reference data are to be submitted for approval and re- view to the Society.

(A) Bar heating and bending including method, temperatures, temperature control and recording

(B) Proof and break loading including method, method of measurement, and recording

(C) Manufacturer’'s surface quality requirement of mooring components

(D) Manufacturing process, manufacturing facilities and Welding machines description according to 1001. (6) (A) (a) and (b)

(E) Working standards

(a)

Inspection organization chart

(b) Contents of inspection at the reception of raw materials

(c)

Bar cutting, heating and bending including method, temperatures, temperature control and recording

(d) Working standards applicable to each size of chain link for flash butt welding (welding current, force, time, flash allowance, upsetting allowance, preheating temperature and pe-

riod, etc.)

(e)

(f)

Flash removal including method and inspection Stud manufacturing process and dimensions

(g) Stud insertion method for stud link chain

(h) Non-destructive examination procedures

(i)

Details of product inspection

3. Calibration of furnaces

Calibration of furnaces shall be verified by measurement and recording of a calibration test piece with dimensions equivalent to the maximum size of link manufactured. Thermocouples are to be placed both on the surface and in a drilled hole located to the mid thickness position of the cali- bration block.

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 43

Ch 2 Approval of Manufacturing Process Ch 2, Sec 10-3

![]()

4. Approval test

(1) Approval test

The approval test is to be carried out on each chain under application for each manufacturing factory. The contents of approval test are to be as indicated in Table 2.10.3 and the test is to be carried out in the presence of the Surveyor unless otherwise specified.

(2) Test chains

The link and test specimens used in the approval test are to be taken from the test chains in the presence of the Surveyor.

5. Changes in the approval content

When major changes are intended to be made in the manufacturing process already approved, the application procedure required for a new approval application is to be taken. The major changes in- clude the items given below where, however, the witness of the approval test by the Surveyor may be dispensed with, or reduction in the approval test items may be accepted for the manufacturer whose product quality control standards and inspection standards are considered appropriate. In this case, however, submission of the results of tests on material properties and related data is required.

(1) Increase in the maximum diameter of chain to be manufactured

(2) Change in casting procedure

(3) Changes in heat treatments (quenching, annealing, tempering, etc.)

(4) New installation of welding machine

(5) New installation of furnace for heat treatment

(6) Other changes for which approval test is considered necessary

1024. Approval of quality system at chain and accessory manufacturers

Chain and accessory manufacturers are to have a documented and effective quality system approved by Ch 2, 104. 2. The quality system is to be additionally submitted during witnessing of tests by Surveyor in order to approve the chain and chain accessories.

1025. Approval of forges and foundries for chain accessories

1. Forges and foundries intending to supply finished or semi-finished accessories are to be approved by the Society. The approval is to be limited to a nominated supplier of forged or cast material. If an accessory manufacturer wishes to use material from a number of suppliers, a separate approval must be carried out for each supplier.

2. The approval will

normally be limited to the type of accessory and

the IACS designated mooring

grade of material up to the maximum diameter or thickness equal to that of the completed ac-

cessory used for

qualification. Qualification of accessory pins to

maximum diameters is also

required. Individual accessories of complex geometries will be subject

to the Society requirements.

3. Forges and foundries are to provide evidence that the manufacturing process produces material that is resistant to strain ageing, temper embrittlement and for R4S and R5 grades, hydrogen embrittlement. A heat treatment sensitivity study simulating accessory production conditions shall be applied in order to verify mechanical properties and establish limits for temperature and time combinations. (Cooling after tempering shall be appropriate to avoid temper embrittlement). All test details and results are to be submitted to the Classification society.

4. For initial approval, Three CTOD tests are to be tested with a standard 2 × 1 single edge notched bend specimen in accordance with a recognized international standard such as BS 7448 Parts 1 &

2. The specimen location is as shown in Table 2.10.3 notes 7. The minimum test piece size shall be 50 × 25 mm for chain diameters less than 120 mm, and 80 × 40 mm for diameters 120 mm and

above. The tests are to be taken at minus 20 ℃ and the results are to be submitted to the Society.

5. Calibration of furnaces shall be verified by measurement and recording of a calibration test piece with dimensions equivalent to the maximum size of link manufactured. Thermocouples are to be placed both on the surface and in a drilled hole located to the mid thickness position of the cali- bration block.

44 Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015

Ch 2 Approval of Manufacturing Process Ch 2, Sec 10-3

![]()

Table 2.10.3 Approval Test Items and Acceptance Criteria for Offshore Chains

Test chains for approval test | |||||||

| |||||||

Test item | Numbers of test specimens | Numbers of test link(exam- ple) | Selection of test specimen and details of test specimen | Test procedure | Acceptance criteria | ||

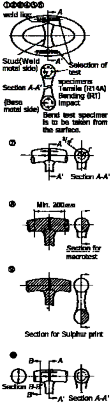

Mechanical properties test of llink | Base metal | ① Tensile test | 1 | No.1 | ⑪

| ①, ②, ④, ⑤ : To conform to Pt 2, Ch 1 of the Rules, The bending radius of Grades R3, R3S & R4 chain ac- cessories is to be 25mm. Grade R4S and R5 chains are to be as deemed ap- propriate by the Society. And the bending angle is to be not less than following angle : 30° for Grade R4, 45° for Grade R3S, 60° for Grade R3. And Grade R4S and R5 chains are to be as deemed appropriate by the Society. ③, ⑥ : Testing temperature of impact test is to be refered to NOTES 6. ⑦ : is to be examined at its center and the point 2/3 r for the structure of HAZ, base metal and weld zone (× 100) ⑧ : Welded portion of link in longi- tudinal section is to be macroetched. ⑨ : Sulphur print of longitudinal sec- tion of link is to be taken. ⑩ : Hardness distribution of base metal and weld zone is to be measured at proper intervals. ⑪ : To be comply with Notes 7 | To conform to Pt 2, Ch 1 of the Rules. |

② Bending test | 1 | No.1 | To be free of harmful defects | ||||

③ Impact test | 3sets | No.3~4 | see NOTES 6. | ||||

Weld zone | ④ Tensile test | 2 | No.1 | Measured tensile strength is to exceed that of the base metal. | |||

⑤ Bending test | 2 | No.2 | To be free of harmful defects | ||||

⑥ Impact test | 3sets | No.3~4 | see NOTES 6. | ||||

⑦ Micro-test | 2 | No.5 | Coarse grain area in HAZ and degree of heat treatment are to be examined. | ||||

⑧ Macro test | 1 | No.5 | To be free of harmful defects | ||||

⑨ Sulphur print | 1 | No.7 | To be free of harmful defects | ||||

⑩ Hardness test | 3 | No.5 | For reference only. However, hardness is to be max 330 for Grade R4S, and 340 for Grade R5. | ||||

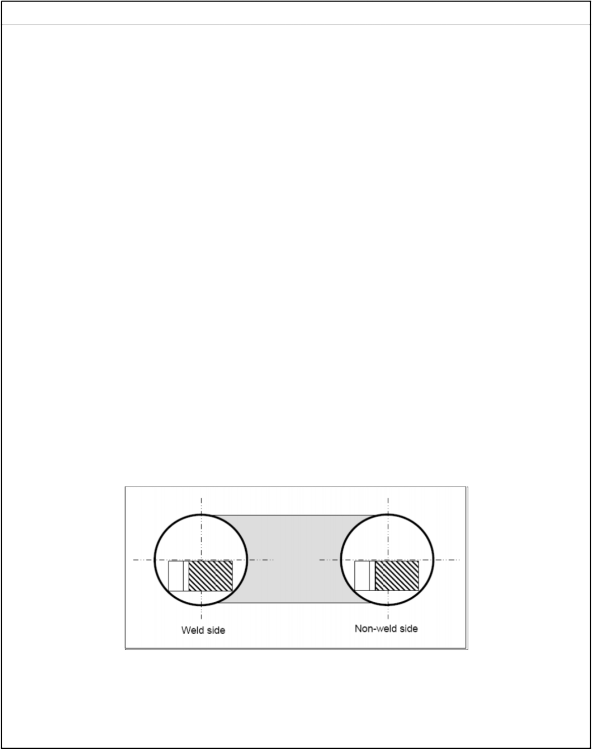

⑪ CTOD test | 6 (from 3 links on each weld side and non-weld side) | No.5 | To be comply with CTOD minimum values of Notes 7 | ||||

Test of testing object of chains | ⑫ Proof test | 2 lengths | No.1~5 No.9~13 | ⑫, ⑬, ⑮, : To conform to Pt 4, Ch 8 of the Rules. ⑭ : After proof test, chain length and dimensions of each link are to be measu | To conform to Pt 4, Ch 8 of the Rules. | ||

⑬ Breaking test | 2 lengths | No.15~19 No.30~34 | Actual breaking load is to be measured in addition to conform to Pt 4, Ch 8 of the Rules. | ||||

⑭ Dimension test | 2 lengths | No.1~5 No.9~13 | Check dimensional changes in addition to conform to Pt 4, Ch 8 of the Rules. | ||||

⑮ Mass in- spection | 2 lengths | No.1~5 No.9~13 | To conform to Pt 4, Ch 8 of the Rules. | ||||

Visual in- spection | 2 lengths | No.1~5 No.9~13 | To conform to Pt 4, Ch 8 of the Rules. | ||||

NOTES; 1. The test links used in the aproval test are to, in principle, be of the desired largest diameter for approval. 2. In the case of cast links, their mechanical properties tests are to be carried out in a manner corresponding to those applied to weld zone. Of those items of test on the testing object, the bending test and compression test may be substituted by magnetic particle testing. 3. When deemed necessary by the Society, non-destructive testing may be requested. 4. In the case of the approval test in association with the change in the manufacturing process as shown in 1203. 5, the diameter and number of test link, or the approval test items may be reduced. 5. When steel materials, manufacturing process or heat treatment methods which are not specified in the Rules are to be employed, the Society may request other tests or submission of reference materials in addition to the specified test items. | |||||||

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 45

![]()

Ch 2 Approval of Manufacturing Process Ch 2, Sec 10-3

Table 2.10.3 Approval Test Items and Acceptance Criteria for Offshore Chains(continue)

Test chains for approval test

6. Temperatures of impact test are to be in accordance with following tables.

Kind of chain | Temperature | Minimum absorbed average energy (J) | |

Base metal | Flash butt weld zone | ||

Grade R3 chain | 0°C, -20°C and -40°C | At 0°C to be of 60J, At -20°C to be of 40J, At -40°C to be with reference. | At 0°C to be of 50J, At -20°C to be of 30J, At -40°C to be with reference. |

Grade R3S chain | At 0°C to be of 65J, At -20°C to be of 45J, At -40°C to be with reference. | At 0°C to be of 53J, At -20°C to be of 33J, At -40°C to be with reference. | |

Grade R4 chain | At -20°C to be of 50J, At other temper- ature to be with reference. | At -20°C to be of 36J, At other temper- ature to be with reference. | |

Grade R4S chain | At -20°C to be of 56J, At other temper- ature to be with reference. | At -20°C to be of 40J, At other temper- ature to be with reference. | |

Grade R5 chain | At -20°C to be of 58J, At other temper- ature to be with reference. | At -20°C to be of 42J, At other temper- ature to be with reference. | |

7. CTOD test required for offshore mooring chain is to comply with the followings

For initial approval, CTOD tests are to be tested in accordance with a recognized international standard such as BS 7448 Parts 1 & 2. The CTOD test piece is to be a standard 2 × 1 single edge notched bend piece, test location as shown in Figure 1. The minimum test piece size shall be 50 × 25 mm for chain diameters less than 120 mm, and 80 × 40 mm for diameters 120 mm and above. CTOD specimens are to be taken from both the side of the link containing the weld and from the opposite side. Three links are to be selected for testing, a

total of six CTOD specimens. The tests are to be taken at minus 20 ℃ and the acceptance criteria is to be

the values and more than the values indicated below:

Chain type | R3 (mm) | R3S (mm) | R4 (mm) | R4S & R5 (mm) | ||||

BM | WM | BM | WM | BM | WM | BM | WM | |

Stud link | 0.20 | 0.10 | 0.22 | 0.11 | 0.24 | 0.12 | 0.26 | 0.13 |

Studless | 0.20 | 0.14 | 0.22 | 0.15 | 0.24 | 0.16 | 0.26 | 0.17 |

BM : Base metal WM : Weld metal

8. For R4S and R5 chain, prior to approval, the manufacturer is to have undertaken experimental tests or have relevant supporting data to develop the chain material. The tests and data may include fatigue tests, hot ductil- ity tests (no internal flaws are to develop whilst bending in the link forming temperature range), welding pa- rameter research, heat treatment study, strain age resistance, temper embrittlement study, stress corrosion crack- ing (SCC) data and hydrogen embrittlement (HE) study, using slow strain test pieces in hydrated environments. Reports indicating the results of experimental tests are to be submitted.

46 Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015

Ch 2 Approval of Manufacturing Process Ch 2, Sec 10-3

![]()

6. Approval test

(1) Approval test

The approval test is to be carried out on each item of chain accessories under application for each manufacturing factory. The details of approval test are to be as indicated in Table 2.10.4 and the test is to be carried out in the presence of the Surveyor unless otherwise specified.

(2) Test chain accessories

The test specimens used in the approval test are to be taken from the test chain accessories un- der application in the presence of the Surveyor.

7. Changes in the manufacturing process

Where major changes significantly affecting the manufacturing process already approved have been made, the requirements in 1023. 5 are to apply.

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 47

![]()

Ch 2 Approval of Manufacturing Process Ch 2, Sec 10-3

![]()

Table 2.10.4 Approval Test Items and Acceptance Criteria for Offshore Chains Accessories

Test item | Numbers of test specimens | Selection of test specimen and details of test specimen | Test procedure | Acceptance criteria | |

Mechanical properties test of chain accessories | ① Tensile test | 2 |

| ① and ② : To conform to Pt 2, Ch 1 of the Rules, The bending radius of Grades R3, R3S & R4 chain accessories is to be 25mm. Grade R4S and R5 chains are to be as deemed appropriate by the Society. And the bending angle is to be not less than following angle : 30° for Grade R4, 45° for Grade R3S, 60°. And Grade R4S and R5 chains are to be as deemed appropriate by the Society. ③ : Testing temperature of impact test is to be refered to NOTES 6. ④ : To be examined at its surface, 2/3 r and center (magnifying power : × 100) ⑤ : Areas shown in the figure are to be macroetched. ⑥ : Sulphur print of the chain accessory in longitudinal section is to be taken. ⑦ : Hardness distribution in diametric di- rection is to be measured at proper intervals. ⑧ : To conform to 1025. 4 ⑨, ⑩, ⑫ : To conform to Pt 4, Ch 8 Sec 4 of the Rules. ⑪ : Measurements of each part of chain accessories after subjected to proof test are to be taken for dimensions. | To conform to Pt 2, Ch 1 of the Rules. |

② Bending test | 2 | To be free of harmful defects | |||

③ Impact test | see NOTES 6 | see NOTES 6. | |||

④ Micro-test | 3 | The degree of heat treatment in diametric direction is to be examined. | |||

⑤ Macro test | 1 | To be free of harmful defects | |||

⑥ Sulphur print | 1 | To be free of harmful defects6. | |||

⑦ Hardness test | 1 | For reference only. However, hardness is to be max 330 for Grade R4S, and 340 for Grade R5. | |||

⑧ CTOD test | 3 | To be as deemed appropriate by the Society. | |||

Tests on testing object of chain accessories | ⑨ Proof test | 1 | To conform to Pt 4, Ch 8 of the Rules. | ||

⑩ Breaking test | 1 | 1.1 times of the specified breaking load is omly required to be loaded, and no actual breaking is required. | |||

⑪ Dimension inspection | 1 | To conform to Pt 4, Ch 8 of the Rules. In addition, dimensional changes are to be measured. | |||

⑫ Visual inspection | 1 | To conform to Pt 4, Ch 8 of the Rules. | |||

NOTES; 1. The test chain accessories used for approval test are to, in principle, be two or three, in number, of the larges diameter under application. 2. The Society, when deemed necessary, may request nondestructive test. 3. In the case of the approval test required in connection with the change in the manufacturing process as shown in 1025. 7, the Society may reduce the requirements in the diamter and number of test chain accessories with respect to the test itmes. 4. When any steel materials, manufacturing process or haat treatment not specified in the Rules are intended to be used, the Society may request other test- ing procedure or submission of reference data in addition to those specified in the Rules. 5. Two specimens for each test of tensile test specimens, bending test specimens and Charpy V-notch impact test specimens are to be taken from the test samples specified in Pt 2, Ch 1, 502. & 603. of the Rules, on both cast and forged chain accessories, tested to satisfy the specified values in addition to the mechanical properties tests given in this Table. 6. Temperature of impact test are to be in accordance with following tables. 7. For R4S and R5 chain accessories, prior to approval, the manufacturer is to have undertaken experimental tests or have relevant supporting data to develop the chain accessory material. The tests and data may include fatigue tests, hot ductility tests (no internal flaws are to develop whilst bending in the link forming temper- ature range), welding parameter research, heat treatment study, strain age resistance, temper embrittlement study, stress corrosion cracking (SCC) data and hydrogen embrittlement (HE) study, using slow strain test pieces in hydrated environments. Reports indicating the results of experimental tests are to be submitted. | |||||

Kind of chain accessories | Number of test specimen | Temperature | Minimum absorbed average energy (J | ) | |||||||||||||||||

Grade R3 chain accessories | 3 | set | 0°C, -20°C and -40°C | At | 0°C | to | be | of | 60J, | At | -20°C | to | be | of | 40J, | At | -40°C | to | be | with | reference |

Grade R3S chain accessories | 3 | set | At | 0°C to be of 65J, | At -20°C | to be | of 45J, At -40°C | to be with reference | |||||||||||||

Grade R4 chain accessories | 3 | set | At -20°C to be | of 50J, At | other | temperature to be | with reference | ||||||||||||||

Grade R4S chain accessories | 3 | set | At -20°C to be | of 56J, At | other | temperature to be | with reference | ||||||||||||||

Grade R5 chain accessories | 3 | set | At -20°C to be | of 58J, At | other | temperature to be | with reference | ||||||||||||||

48 Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015

![]()

Ch 2 Approval of Manufacturing Process Ch 2, Sec 11

![]()